Recently, at Unit 4 of the Mochovce Nuclear Power Plant (EMO), we faced a significant challenge when post-assembly inspections revealed a defective weld on a DN 150-diameter pipe. This pipe is in the spent fuel storage pool, where a specialized workspace had to be established under the strictest clean assembly standards. Additionally, the pipe was embedded in a concrete monolith, allowing repair only from the inside. To make matters more challenging, the weld was approximately 1000 mm from the accessible pipe entry, further complicating the situation.

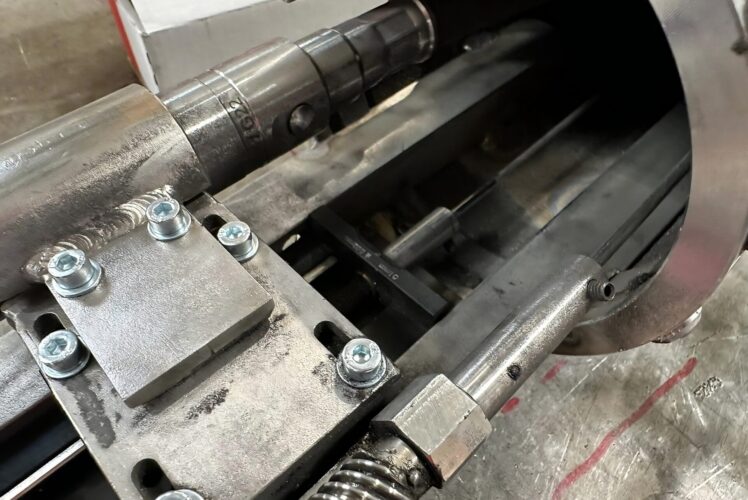

Footage from our workshop

To address this challenge, we opted for an unconventional approach. In collaboration with POLYSOUDE, a leader in mechanized welding, we decided to use a specialized orbital welding setup with TIG 141 technology (tungsten inert gas arc welding). Our technicians developed a special prototype, using grinding to create the necessary bevel. After fine-tuning the parameters and approving the procedures (WPQR and WPS), we proceeded with the repair on-site

Footage from our workshop

We inspected each weld layer using an endoscope, maintaining stringent oversight of the entire process conducted in clean assembly conditions typical of a nuclear power plant. Rigorous control and preparation, including simulations and tests, allowed us to complete the repair. This complex process demonstrated that thanks to our team’s innovative approach, we can solve issues even under the most demanding conditions.